Precise Inspection of Surfaces on the running (production) line

Examples of Surface Inspection

The control of surfaces enables precise quality assurance in the ongoing production process. Abnormalities such as scratches, scratches or material inhomogeneities are identified by the NeuroCheck camera inspection system early on and reject defective parts. Even with very low cycle times, the NeuroCheck Software works safely and reliably.

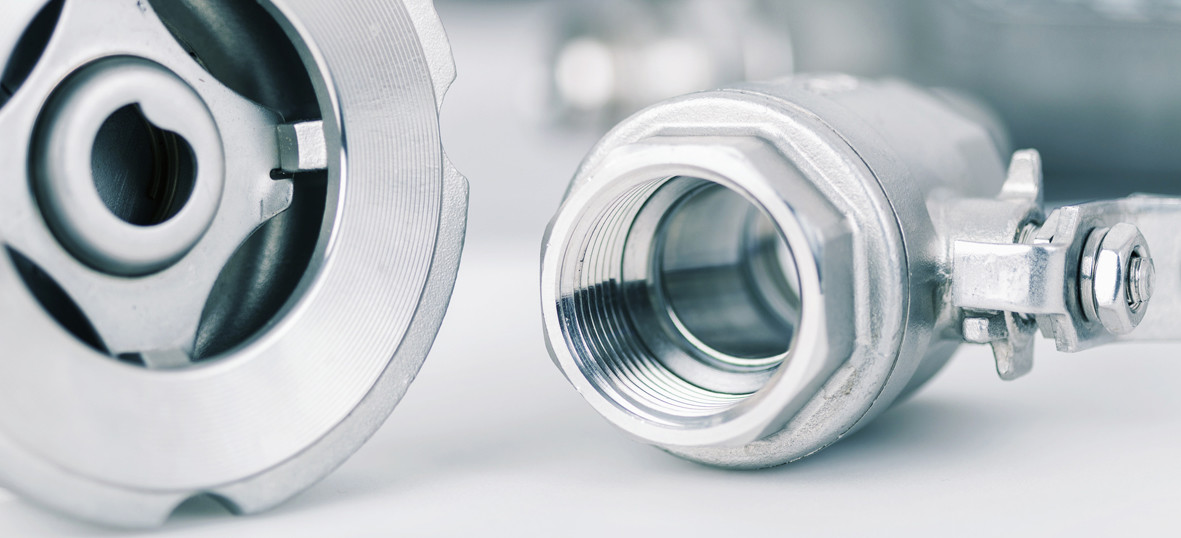

Surface Inspection on safety-critical valve bodies

This application example shows a complex line camera application, in which the valve bodies are checked for defects in the servo steering system. Firstly, the prescribed number of holes must be in the correct size and position. Secondly, the raised treads between the punches must be absolutely smooth. The two tests are taken in two line camera shots on the rotated test part, one with light field and one with dark field illumination.

Inspection of polished surfaces

At first sight, polished surfaces look homogeneous and without great variance. However, when you look closely, you can see scratches, voids, gaps and faults in the cut. In addition, in the case of ground surfaces, the difference in the reflection properties between the dressing intervals of the grinding wheel must also be considered. With an innovative lighting concept, the surface can be safely tested despite the different reflection characteristics.

Edge Inspection on flat glass panes

This application is concerned with the inspection of flat screens, computer monitors and small displays – the flat glass is the common feature of all these devices. During the production of the up to 3x3m large disks, which are only up to 0.4 mm thick, the glass edges have to be checked for various defects such as cracks, noses, peaks, eruptions and misalignment. The detection can be carried out during transport with e.g. 80 m / min by means of several digital line cameras.

Surface Inspection on Ceramic Tube

Due to the structure of ceramic materials, damage can only be represented and evaluated with a special lighting concept. For the control of the end face on ceramic tubes, e.g. A 4-quadrant illumination is used. In this method, 4 images are recorded, each with an illumination mounted at a different angle to the test part. The images are processed in the NeuroCheck software by linking the 4 images. In the result image, the errors are worked out in a contrasting manner.

Images Header, Ceramic Tube © NeuroCheck

Image Valve Bodies © designed by murmakova – Fotolia

Image Polished Surfaces © designed by nordroden – Fotolia

Image Flat Screens © designed by selensergen – Fotolia

Image Contact © designed by Pressfoto – Freepik.com