Inspection in the assembly ensures product quality

Examples for Assembly Control

Where people with high production speed can no longer keep up, NeuroCheck system solutions ensure the quality in the production process every second via assembly control. Thus, certain assembly steps are fully automatically checked for presence, completeness, type differentiation and installation position. In the same step, components or even entire assemblies can be measured. Manufacturing processes can be directly optimized with the obtained measurement results.

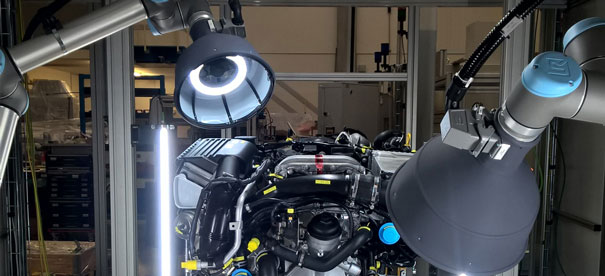

Final Motor Inspection with a Robot

Different motor variants are automatically tested in the test cell for the presence of the correct components. The robot positions the camera according to the motor type to the corresponding test positions. In the NeuroCheck solution for end-of-engine control, the type management is carried out via an SQL database, in which new model variants are created interactively in the database. The existing test patterns can be re-used without re-programming.

Final Motor Inspection with Pan / Tilt / Zoom Cameras

Flexible assembly concepts with changing product variants require image processing systems that can manage a variety of test patterns and dynamically generate test sequences. By using industry-standard pan / tilt / zoom cameras, such flexible test concepts can be easily implemented. The starting positions for each camera are either taught in advance or can be dynamically adjusted even from the test sequence.

Pressing in a Rubber Band

For vehicle steering parts, rubber bearings are pressed as damping elements. For different bearings, pressing in a defined angular position is necessary. With the NeuroCheck system, the parts are reliably detected and the angle of rotation is determined and verified even with small contrast differences.

Images Header, Robot © NeuroCheck

Image Pan / Tilt / Zoom Cameras © Optotune Switzerland AG

Image Rubber Band © designed by Dezay – Fotolia

Image Contact © designed by Pressfoto – Freepik.com